How much does it cost to manufacture a tampon in 2026?

On average, the production cost for a single tampon unit ranges from $0.05 to $0.15 USD. This unit price is influenced by three primary factors: material selection (Organic Cotton vs. Rayon), applicator design (Plastic vs. Cardboard), and the total order volume (MOQ). For premium private label brands, additional costs include FDA/CE compliance testing and customized eco-friendly packaging.

1. Introduction to Tampon Production Economics

In the rapidly evolving feminine hygiene market, understanding the unit economics of production is vital for brands aiming to balance quality and profitability. As a leading manufacturer, we break down the cost components that define the wholesale price of tampons in today’s global supply chain.

2. Raw Material Costs: Organic vs. Conventional

The absorbent core is the most significant cost driver.

- 100% GOTS Certified Organic Cotton: Generally costs 15-20% more than standard rayon or blended fibers. This is the preferred choice for high-end markets like Sweden, the UK, and the US.

- Rayon (Viscose): Provides excellent absorbency and a more stable, lower price point. It remains the industry standard for mass-market retail products.

- Emerging Sustainable Fibers: Materials like bamboo or hemp are becoming popular but currently carry a premium due to specialized processing requirements.

3. Applicator and Component Costs

The applicator often costs as much as the absorbent core itself.

| Component | Material | Cost Level | Market Trend |

| Applicator | BPA-free Plastic | Low | High demand in North America |

| Applicator | Flushable Cardboard | Medium | Growing in UK & EU due to plastic bans |

| Wrapper | Paper or Bio-film | Medium | Essential for “Plastic-Free” branding |

| Withdrawal Cord | High-Tension Cotton | Stable | Standard across all tiers |

4. Hidden Costs: Compliance and Medical-Grade Standards

Tampons are classified as medical devices in many regions (Class II by the FDA). Therefore, “cost” must include safety verification:

- FDA 510(k) Clearance: Essential for selling in the USA.

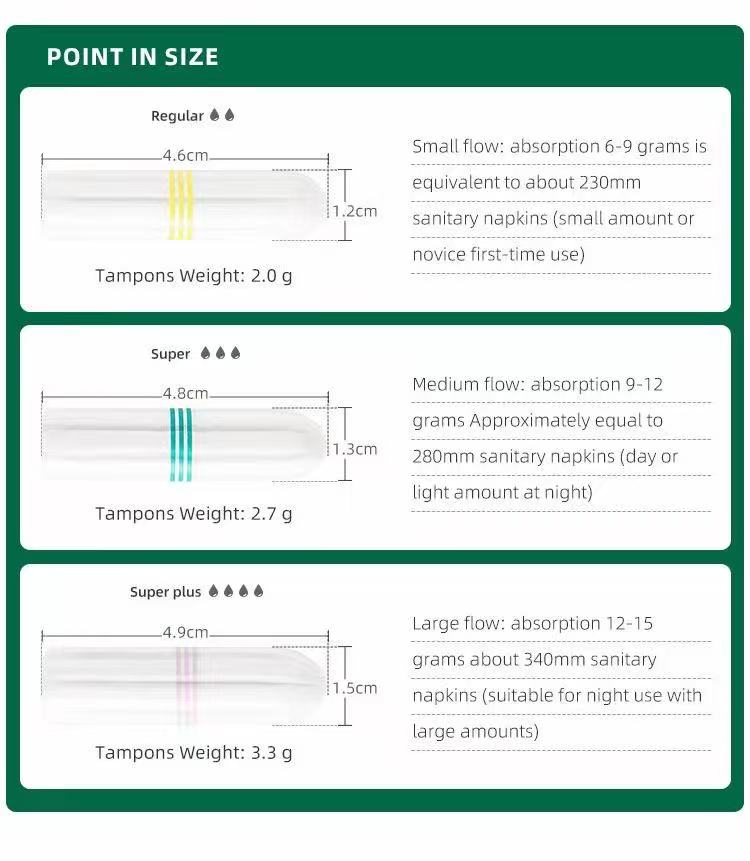

- Syngina Testing: Ongoing laboratory tests to ensure absorbency consistency across Regular, Super, and Super Plus sizes.

- Ethylene Oxide (EO) Sterilization: Ensures the product is free from microbial contamination.

5. How Volume Affects Your Bottom Line (MOQ)

Minimum Order Quantities (MOQs) are crucial for cost efficiency.

- Small Batches (50k – 100k units): Higher per-unit cost due to machine setup and packaging plates.

- Bulk Orders (500k+ units): Significant “economies of scale,” often reducing the per-unit price by 10-15%.

6. Conclusion: Choosing the Right Strategy

For B2B buyers, the cheapest option isn’t always the most profitable. Investing in organic materials or biodegradable applicators can allow for a 2x-3x higher retail markup, especially in environmentally conscious markets like Northern Europe and the United Kingdom.

FAQ

Q1: Can I get a fixed price per box of 20 tampons?

A: Wholesale pricing is usually quoted per 1,000 units. A standard box of 20 private-label tampons typically costs between $1.20 and $2.80 at the factory level, depending on the specifications.

Q2: Does the location of the factory impact the cost?

A: Yes. While labor costs vary, the proximity to raw cotton sources and shipping ports significantly affects the final “landed cost.”

Q3: Are there extra costs for custom printing?

A: Custom wrapper and box printing usually involve a one-time “plate charge” per color, which is amortized over your total order volume.