Certified Tampon Factory Serving Global Markets

In the global female hygiene industry, choosing the right tampon manufacturer is a critical decision that directly affects product safety, regulatory compliance, brand reputation, and long-term business growth. Unlike general consumer goods, tampons are classified as intimate hygiene products, which means manufacturing standards are significantly higher and mistakes can carry serious consequences.

This page provides a comprehensive, factory-level overview of what a professional tampon manufacturer is, how tampon manufacturing works, and how OEM and private label partners can build safe, scalable, and compliant supply chains. Whether you are launching a new tampon brand or expanding an existing product line, understanding the manufacturing foundation is essential.

What Is a Professional Tampon Manufacturer?

A professional tampon manufacturer is a factory that specializes in the production of tampons, operating dedicated production lines under controlled hygienic conditions and structured quality management systems. Unlike traders or resellers, a true manufacturer is directly responsible for every critical step of production—from raw material selection to final packaging and inspection.

Manufacturer vs Trader: Why the Difference Matters

In international sourcing, many buyers encounter suppliers that present themselves as manufacturers but operate primarily as intermediaries. The difference is significant:

- Manufacturers control production processes, quality systems, and hygiene environments

- Traders outsource production and have limited control over consistency and compliance

For brands and distributors, working directly with a tampon factory reduces risk, improves transparency, and ensures a stable, long-term supply.

For buyers evaluating potential partners, understanding production control, hygiene standards, and compliance capability is essential. This step-by-step guide explains how to choose a tampon manufacturer from a professional sourcing perspective.

The Role of the Manufacturer in Brand Success

A professional tampon manufacturer is not just a production vendor. It plays a central role in:

- Ensuring consistent absorption performance

- Maintaining hygiene and contamination control

- Supporting regulatory and compliance requirements

- Scaling production as demand grows

For OEM and private label brands, the manufacturer becomes an operational extension of the brand itself.

Tampon Manufacturing Capabilities Overview

Professional tampon manufacturing requires a combination of specialized equipment, automation, skilled personnel, and strict process control. Factories that meet international expectations invest heavily in dedicated tampon production infrastructure.

Core Manufacturing Capabilities

A qualified tampon factory typically supports the following core processes:

- Absorbent core forming using medical-grade cotton or blended fibers

- Compression control to ensure comfort and consistent expansion

- Withdrawal string attachment with controlled tensile strength

- Applicator assembly for applicator-type tampons

- Hygienic individual packaging

Each of these processes must be precisely controlled to maintain product safety and user comfort.

These capabilities are supported by a structured factory workflow. To better understand each stage in detail, you can review our explanation of the professional tampon manufacturing process from raw materials to finished products.

Automation and Production Scalability

Modern tampon manufacturing relies heavily on automated production lines. Automation reduces human contact, improves consistency, and enables scalable output. Advanced factories design their production systems to support:

- Stable output across multiple product specifications

- Efficient changeover between absorbency levels

- Long-term capacity expansion without quality loss

For growing brands, scalability is a key indicator of manufacturing reliability.

Tampon Manufacturing Process Explained (Factory View)

Understanding how tampons are made provides valuable insight into how quality, safety, and consistency are achieved. Below is a high-level overview of the professional tampon manufacturing process, explained from a factory perspective.

1. Raw Material Selection and Inspection

Tampon production begins with the selection of medical-grade absorbent materials, typically cotton or carefully engineered fiber blends. Raw materials are evaluated based on:

- Absorption capacity

- Fiber uniformity

- Cleanliness and purity

- Skin safety

Before entering production, all materials undergo incoming quality inspection to ensure they meet internal and market-specific standards.

2. Absorbent Core Forming and Compression

The absorbent material is processed through automated equipment that forms it into cylindrical tampon cores. At this stage, factories carefully control:

- Weight consistency

- Density and compression level

- Shape uniformity

This step is critical because it directly affects absorption performance and comfort during use.

3. Withdrawal String Attachment

Each tampon core is fitted with a withdrawal string using automated systems. String attachment must meet strict requirements for:

- Tensile strength

- Secure anchoring

- Accurate positioning

Improper string attachment is a serious safety risk and is closely monitored during production.

4. Applicator Assembly (If Applicable)

For applicator tampons, the compressed core is inserted into an applicator made from medical-grade plastic or cardboard. Applicator assembly requires:

- Precise alignment

- Smooth surface finishing

- Reliable push-out functionality

Factories often operate separate production modules for applicator and non-applicator products.

5. Hygienic Individual Packaging

After assembly, tampons are individually wrapped to protect them from contamination during storage and transportation. Packaging materials are selected to balance hygiene protection, cost efficiency, and market preferences.

6. Final Inspection and Testing

Before shipment, finished products undergo final inspection and testing, which may include:

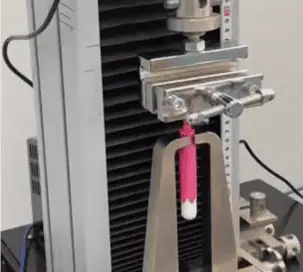

- Absorption performance testing

- String tensile strength testing

- Metal detection

- Visual inspection

These controls ensure that only compliant products reach the market.

Quality, Safety, and Compliance Standards

Quality and safety are the foundation of professional tampon manufacturing. Because tampons are intimate hygiene products, factories must operate under strict hygiene and quality management systems.

Quality Control Systems

A structured quality control system typically includes:

- Incoming raw material inspection

- In-process monitoring at critical control points

- Final product inspection and testing

- Batch documentation and traceability

Quality is managed as a continuous process, not a single checkpoint.

These systems are designed to meet strict tampon factory quality and safety standards, covering raw material inspection, in-process control, and final product testing.

Hygiene and Cleanroom Management

Professional tampon factories operate controlled production environments designed to minimize contamination risk. These environments include:

- Cleanroom or controlled-area production zones

- Air filtration and environmental control systems

- Strict personnel hygiene protocols

Employee training and discipline are essential elements of hygiene management.

Cleanroom environments and personnel discipline are critical for contamination prevention. Learn more about our cleanroom and hygiene management practices in professional tampon manufacturing.

Compliance and Market Support

Different markets have different regulatory expectations. Experienced manufacturers support buyers by providing:

- Documentation aligned with international quality systems

- Testing support for target markets

- Export compliance experience

This support reduces risk for brands entering regulated markets.

OEM and Private Label Tampon Manufacturing

OEM and private label manufacturing allow brands to bring products to market without building their own production facilities. In tampon manufacturing, OEM cooperation requires close coordination between the brand and the factory.

What OEM Means in Tampon Manufacturing

In an OEM model:

- The factory provides production expertise and infrastructure

- The brand defines product specifications and market positioning

- Both parties collaborate to ensure quality, compliance, and consistency

This model enables faster market entry and lower initial investment.

Many international brands choose OEM and private label tampon manufacturing to reduce upfront investment while maintaining control over quality and brand positioning.

Customization Options

Professional tampon manufacturers typically support customization in areas such as:

- Absorbency levels (Light, Regular, Super)

- Applicator or non-applicator designs

- Core material composition

- Individual wrapping and retail packaging

- Private label branding

Customization must always be balanced with production efficiency and quality control.

Confidentiality and Brand Protection

Reputable manufacturers respect brand confidentiality and intellectual property. Long-term cooperation is built on trust, transparency, and mutual growth.

MOQ, Trial Orders, and Production Scalability

Minimum order quantity (MOQ) is a common concern for new and growing brands. In tampon manufacturing, MOQs exist to ensure production efficiency and quality stability.

For new and growing brands, flexibility is essential. Our approach to MOQ and trial orders allows partners to validate quality and market response before scaling production.

Understanding MOQ in Tampon Production

MOQs are influenced by:

- Product complexity

- Packaging customization

- Equipment setup requirements

- Quality testing scope

Professional factories explain MOQ clearly and help buyers understand the rationale.

Trial Orders as a Risk-Reduction Strategy

Many manufacturers support trial orders that allow buyers to:

- Test product quality

- Validate market acceptance

- Evaluate logistics and communication

Trial orders are a practical step between samples and mass production.

Scaling with Confidence

As demand grows, manufacturers support scaling by:

- Planning capacity in advance

- Optimizing production efficiency

- Maintaining consistent quality across larger volumes

Scalability is a key indicator of a reliable manufacturing partner.

Why Global Brands Choose Our Tampon Factory

As a China-based tampon manufacturer, we combine automated production, cost efficiency, and export experience to support global OEM and private label brands.

In a market where product safety, regulatory compliance, and supply stability are critical, global brands choose manufacturing partners based on capability, reliability, and long-term value, not short-term pricing.

Professional buyers work with tampon manufacturers that demonstrate the following characteristics:

- Manufacturing focus – dedicated tampon production lines rather than mixed or outsourced facilities

- Quality consistency – stable absorption performance and controlled production parameters

- Hygiene discipline – cleanroom environments and strict contamination control

- Export experience – familiarity with international documentation and logistics

- Clear communication – efficient coordination across time zones and markets

These factors reduce operational risk and support sustainable brand growth.

Rather than positioning ourselves as a low-cost supplier, we focus on being a reliable manufacturing partner that supports brands throughout their development lifecycle.

Who We Work With

Our tampon manufacturing solutions are designed to support a wide range of professional buyers across global markets.

Typical Clients Include:

- Private label tampon brands launching or expanding product lines

- Importers and distributors supplying pharmacies, supermarkets, and online platforms

- Retail chains are developing store-brand feminine hygiene products

- Entrepreneurs and startups entering the female hygiene market

By working closely with each client, we adapt manufacturing solutions to match their market strategy, volume expectations, and compliance requirements.

Frequently Asked Questions (FAQ)

The following questions reflect the most common concerns raised by international buyers when sourcing from a professional tampon manufacturer.

Are you a direct tampon manufacturer or a trading company?

We operate as a direct tampon manufacturer with dedicated production lines and in-house quality control systems. All key production processes are managed within our factory, ensuring transparency and consistency.

Do you support OEM and private label tampon manufacturing?

Yes. We provide OEM and private label manufacturing services, including product customization, packaging design support, and brand confidentiality protection.

What is your minimum order quantity (MOQ)?

MOQ depends on product type, packaging requirements, and customization level. We also support trial orders for qualified projects to help brands validate quality and market response before scaling.

Which markets do you export to?

We support export-oriented manufacturing and work with clients serving multiple international markets. Our team is familiar with export documentation and market-specific compliance expectations.

How do you ensure product quality and safety?

Quality and safety are managed through:

- Structured quality control systems

- Cleanroom production environments

- In-process and final product testing

- Batch traceability and documentation

These systems are designed to meet international hygiene and safety expectations.

Can you scale production as our brand grows?

Yes. Our production planning and automation systems are designed to support scalable manufacturing, allowing brands to grow without sacrificing quality or delivery reliability.

Start Your Tampon Manufacturing Project Today

Choosing the right tampon manufacturer is a strategic decision that affects every aspect of your product—from safety and compliance to customer trust and long-term profitability.

By working with a professional tampon factory, brands benefit from:

- Controlled and hygienic manufacturing environments

- Consistent product quality

- OEM and private label flexibility

- Scalable production capacity

- Export-oriented operational support

Whether you are launching a new tampon brand or expanding an existing portfolio, a strong manufacturing foundation is essential for success.

👉 Request Manufacturing Details & OEM Solutions

If you are looking for a professional tampon manufacturer to support your project, we invite you to contact us for:

- Manufacturing capability overview

- OEM and private label options

- Trial order and MOQ guidance

- Quality, compliance, and export support

Get in touch today to discuss your tampon manufacturing requirements with an experienced factory partner.