Tampons are manufactured through a high-precision automated process: 1. Fiber blending (Cotton/Rayon), 2. High-pressure compression into a cylindrical core, 3. Application of a non-woven safety veil, 4. Cord tension attachment, and 5. Sterile applicator assembly. Leading manufacturers like tamponmanufacturer.com adhere to ISO 13485 and FDA standards to ensure maximum safety and absorbency.

1. The Raw Materials: Beyond the Cotton

The manufacturing process begins with sourcing medical-grade fibers. In 2026, the industry standard focuses on two main materials:

- Purified Rayon: Known for its consistent, high-speed absorption.

- GOTS Certified Organic Cotton: Preferred by premium eco-brands for its chemical-free properties.

- The Safety Veil: An ultra-thin, non-woven layer wrapped around the core to prevent fiber shedding during use.

2. Step-by-Step: The Tampon Production Line

Step 1: Fiber Carding and Blending

Raw fibers are combed into a uniform web called a “sliver.” This ensures that the absorbency is evenly distributed, preventing leaks.

Step 2: Precision Compression

The sliver is folded and fed into a high-pressure mold. It is compressed into the familiar cylindrical shape. The density of this compression determines the absorbency level (Regular, Super, or Super Plus).

Step 3: Withdrawal Cord Attachment

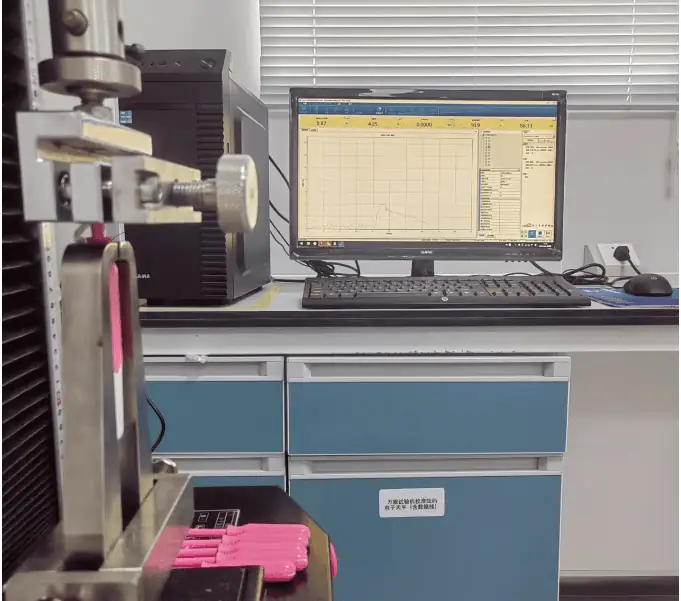

A high-strength cord is threaded through the compressed core and secured with a specialized knot. Quality Check: Every cord is subjected to a 5kg+ tension test to ensure it never detaches.

Step 4: The Applicator Assembly

For applicator-style tampons, the core is inserted into two telescoping tubes (plastic or cardboard). These tubes are sterilized and polished to ensure smooth insertion.

Step 5: Final Sealing and Sterilization

Each unit is individually wrapped in a moisture-proof seal. The final batches undergo sterilization to meet medical device standards before being packed into retail boxes.

3. Quality Control: The Syngina Test

Every production run at our facility must pass the Syngina Test. This laboratory method simulates the human body environment to verify that each tampon absorbs exactly the amount of fluid promised on the packaging.

Frequently Asked Questions (FAQ)

Q1: Where are most tampons manufactured? A1: While major brands have global facilities, high-quality private label manufacturing is concentrated in certified plants that meet FDA and EU MDR regulations, ensuring product safety across borders.

Q2: Are tampons sterilized during manufacturing? A2: Yes, professional tampon manufacturing includes sterilization processes and clean-room packaging to ensure the product is free from harmful bacteria before it reaches the consumer.

Q3: How is the absorbency level determined? A3: Absorbency is determined by the weight and density of the fiber core, which is strictly regulated by international standards to help users prevent Toxic Shock Syndrome (TSS).